-

Company

-

Products

-

Newsroom

-

Recruitment

-

Customer

Efficient AMHS Solutions

It automates transport and storage in semiconductor fabs, ensuring precise FOUP handling,

optimized space utilization, and seamless system for stable and efficient operations.

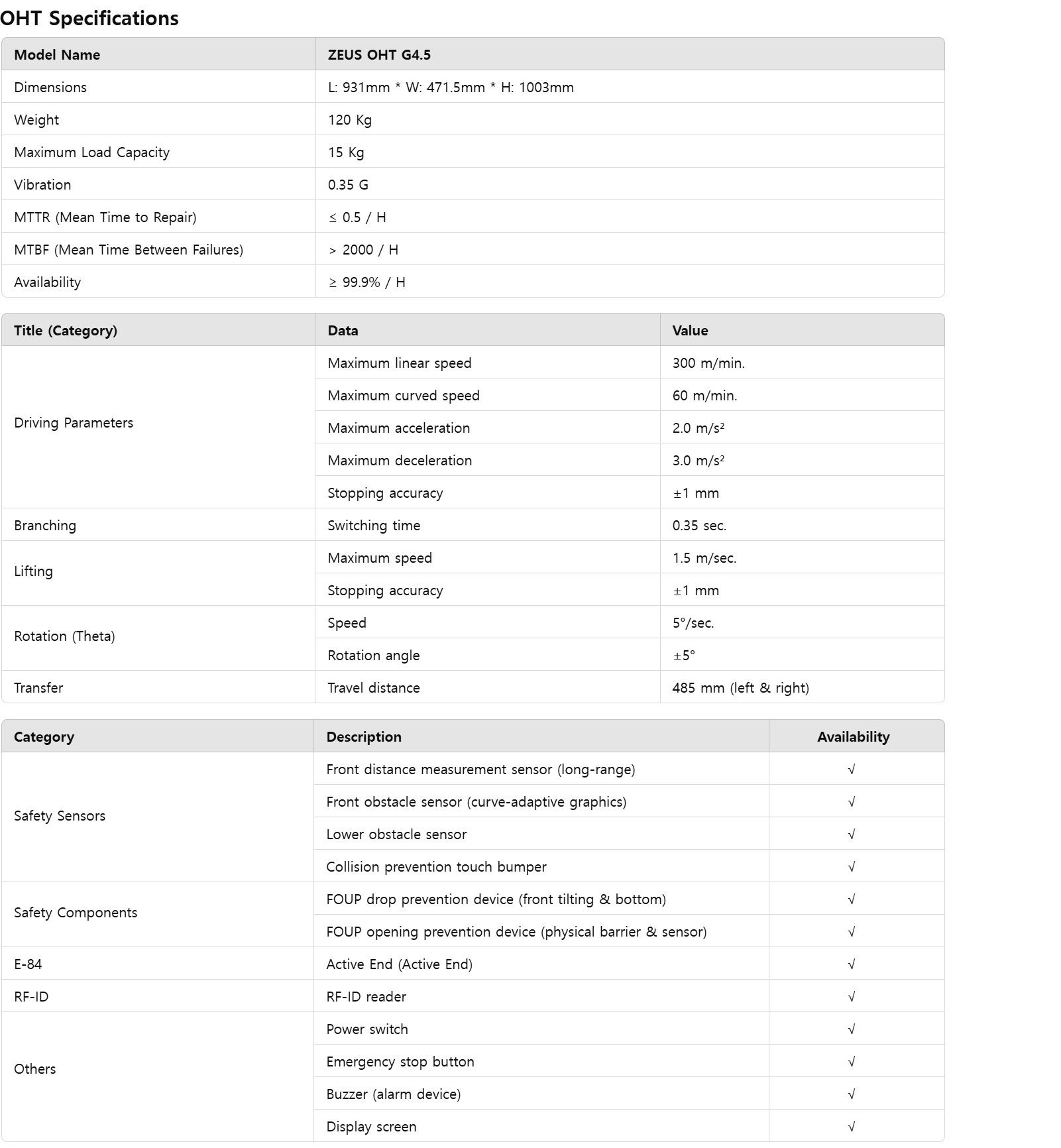

OHT (Overhead Hoist Transfer)

This overhead automated transport system handles the automatic transfer of FOUPs

in semiconductor processes. It integrates seamlessly with Stockers/EQ using the E84 standard communication

protocol for semiconductor equipment and complies with SEMI standards, ensuring smooth data interaction with

higher-level systems. The system uses contactless power supply to meet cleanroom requirements, achieving

Class 100 cleanliness standards.

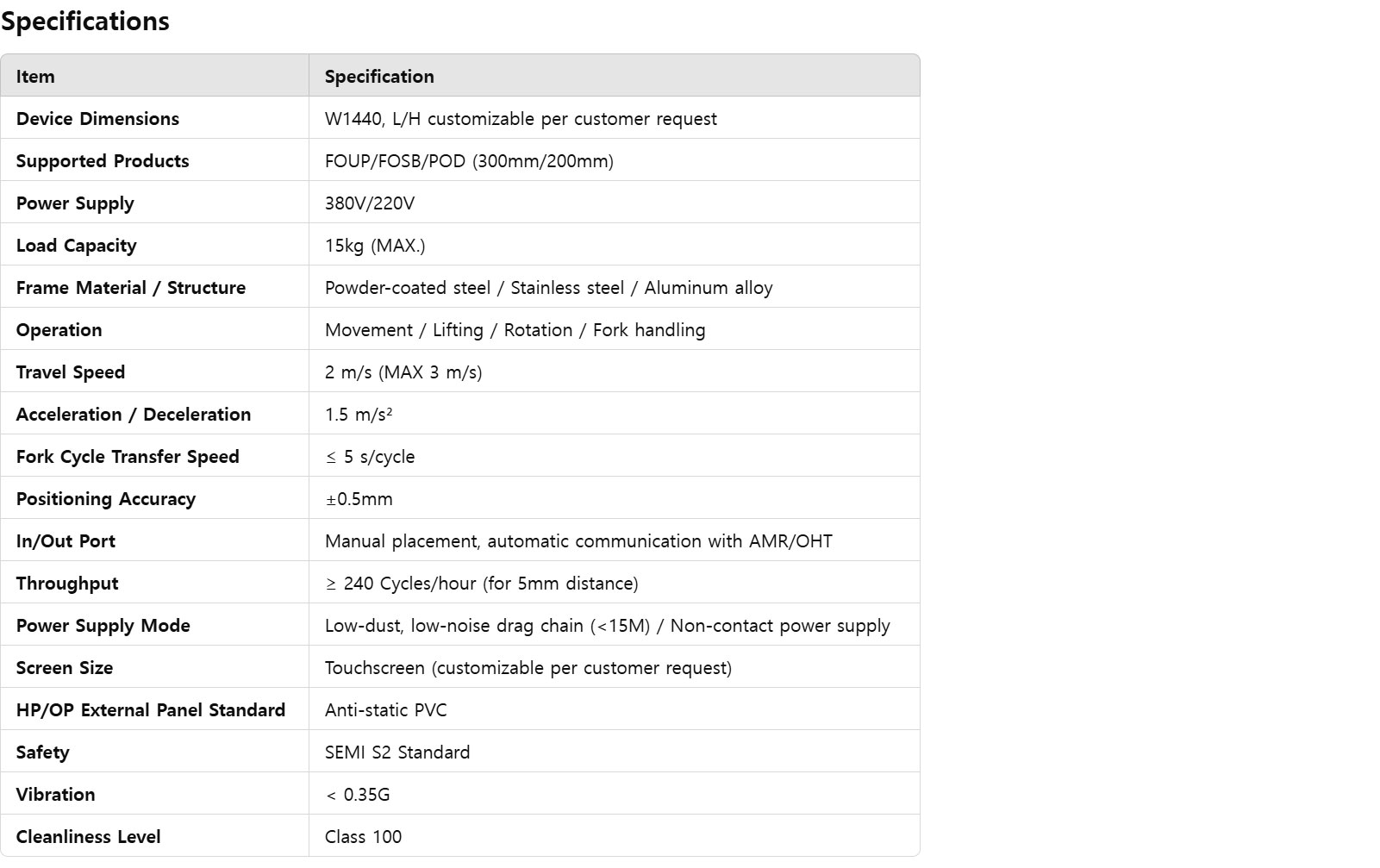

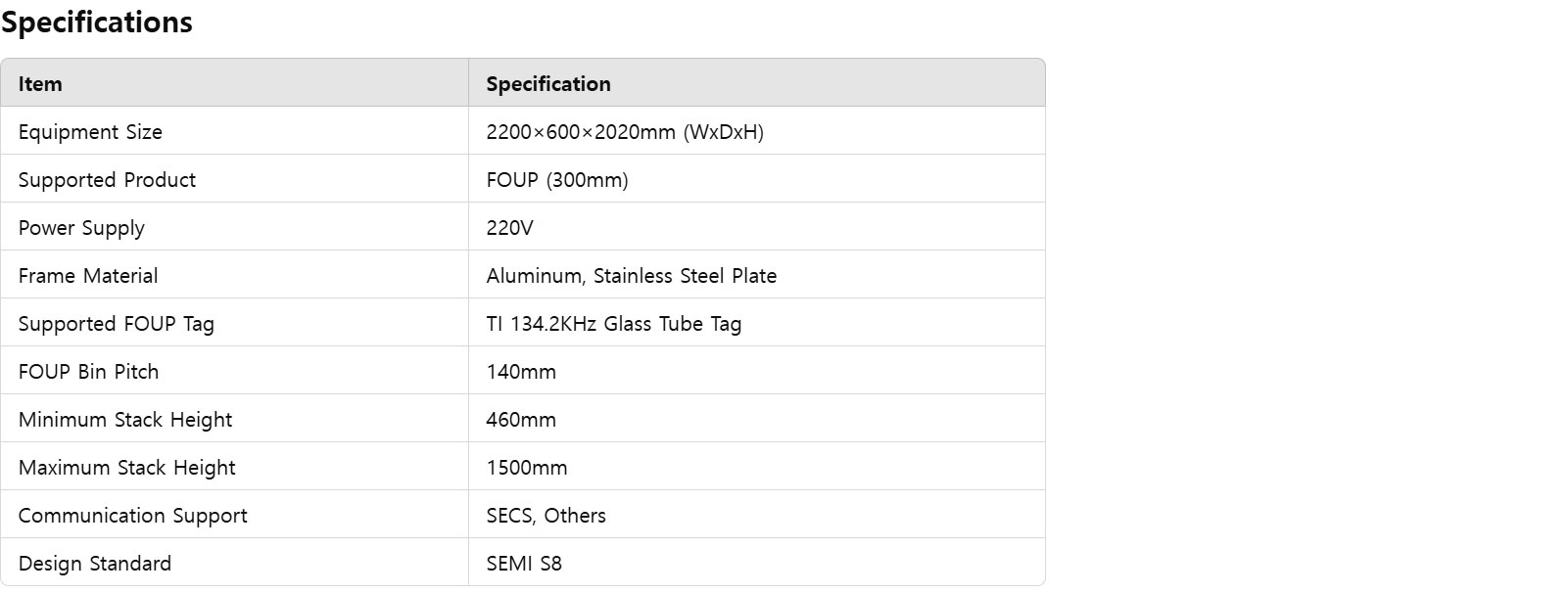

Stocker

Stocker uses 300/200mm FOUP standard SEMI carriers in semiconductor applications.

It interfaces seamlessly with OHT via the E84 standard, enabling automatic loading and unloading

operations without manual intervention while interacting with the MES system in real time.

By integrating various status data, it supports the design of smart factory management modules,

offering efficient development tailored to customer needs and site conditions.

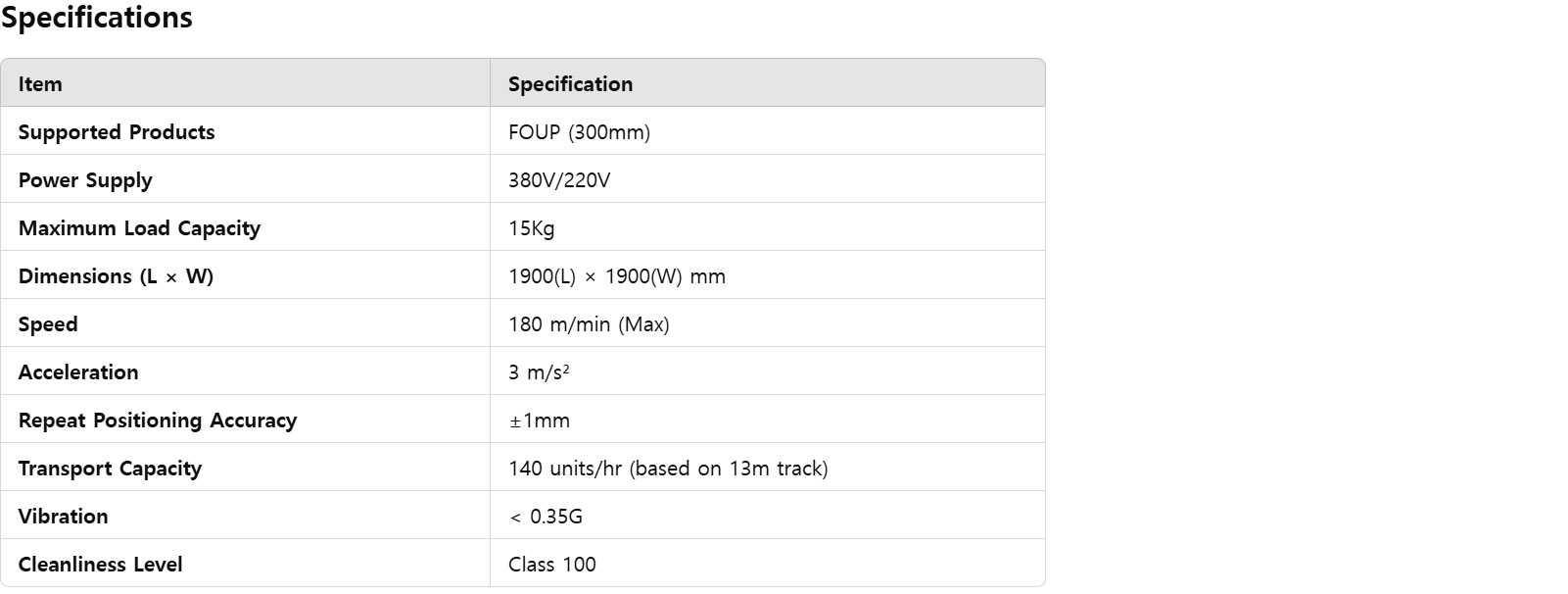

Tower Stocker

The Tower Stocker is designed for efficient wafer storage and management.

It features a vertical storage tower with multiple horizontal wafer racks, enabling high-capacity storage and

easy access to individual wafers. The system allows for automated management, minimizing manual intervention

while improving the efficiency and accuracy of production lines.

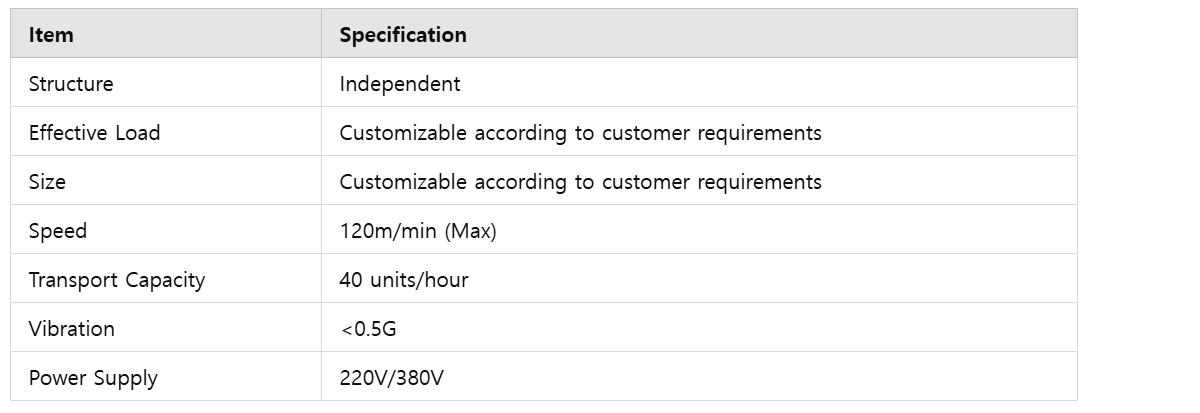

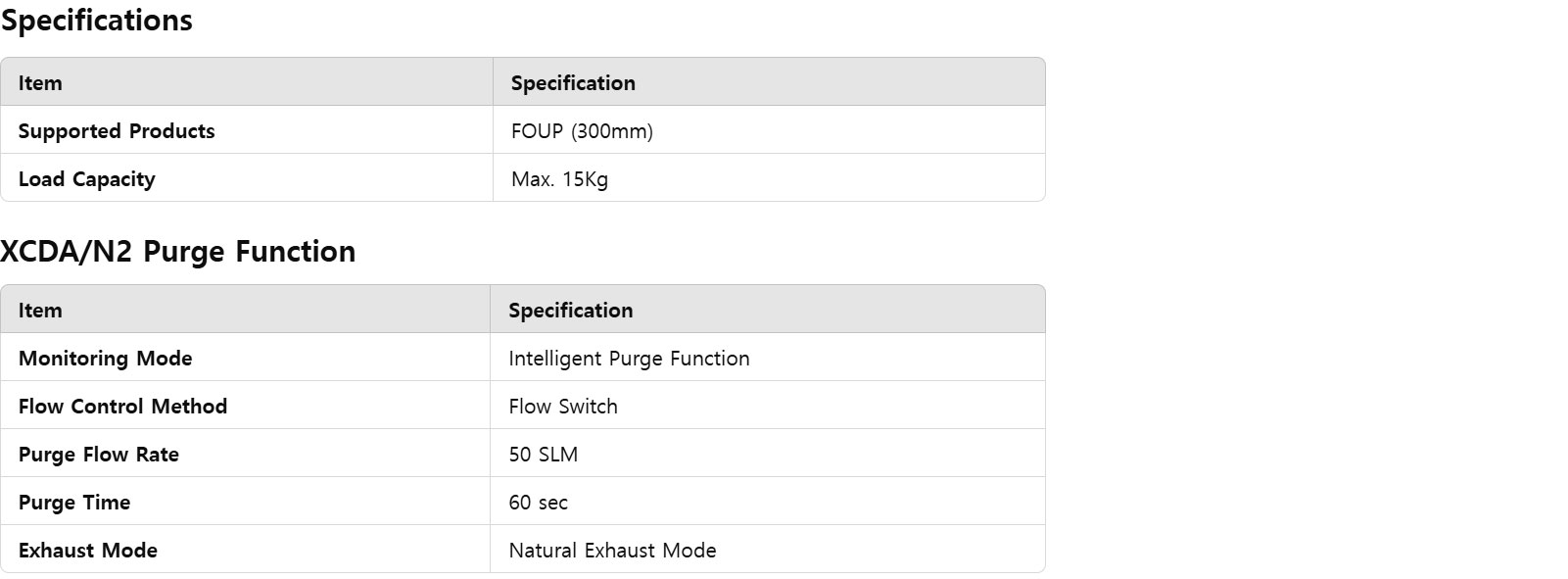

Lifter

The Lifter plays a key role in transferring silicon wafers between different floors in semiconductor production.

Through advanced automation, it ensures fast, precise, and efficient operations, significantly reducing the reliance on manual labor and minimizing errors in the production process. The Lifter can seamlessly integrate with other AMHS equipment, including conveyor and storage systems, to form a fully automated logistics network. A central control system manages these integrations, enabling complete automation of production lines. The AMHS Lifter is an indispensable part of modern semiconductor manufacturing, offering enhanced efficiency, reliability, and production quality.

OHB

The OHB is a storage device installed below the ceiling to hold FOUPs.

It interfaces automatically with OHT systems, minimizing floor space usage and allowing for the

installation of additional production equipment. The OHB utilizes space efficiently to increase

FOUP storage capacity in confined areas.

E-Rack

The E-RACK manages logistics information for FOUP/POD in semiconductor wafer processes.

It communicates with the upper MES system to provide real-time location updates, reducing

manual search time and improving production management efficiency.

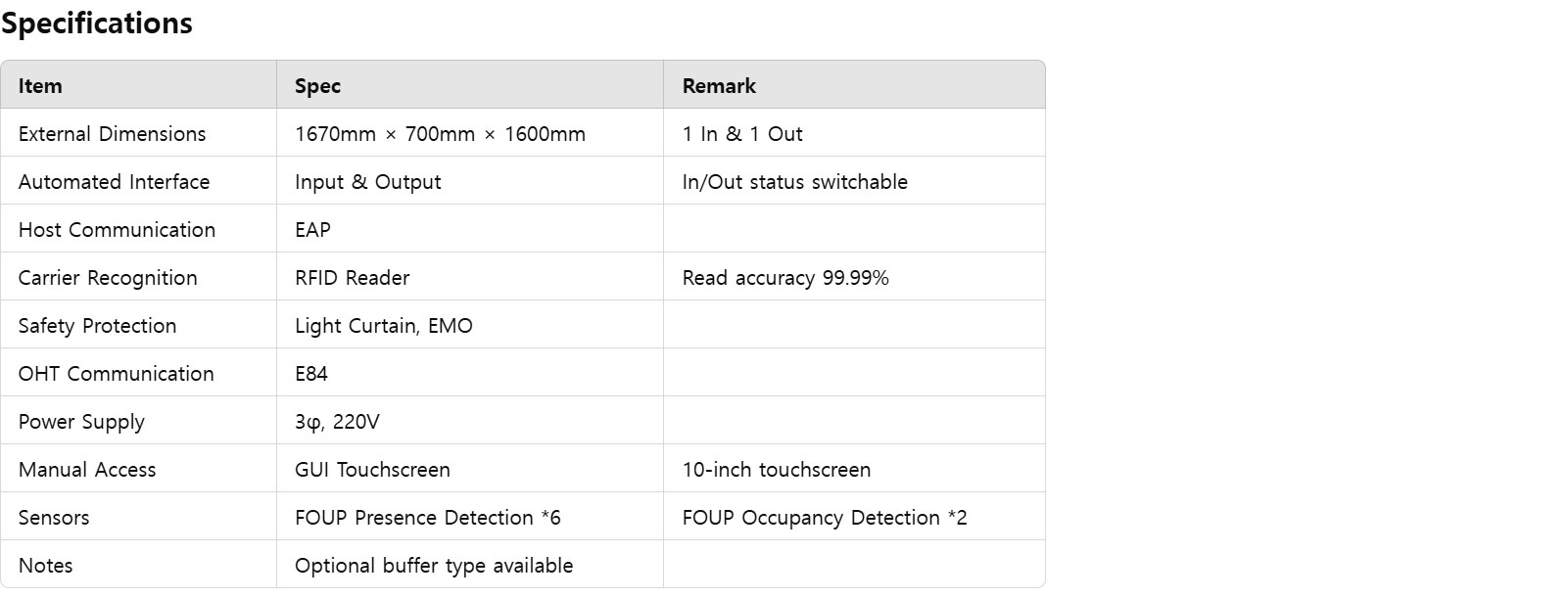

Manual Station

The Manual Workstation (MS) is a node in an automated production line or workflow, typically requiring manual intervention and operation. It can communicate with the upper-level MES to handle specific tasks that the automated system cannot easily complete.

개인정보 처리방침